What is the Role of Label Machine in Modern Manufacturing?

In today’s fast-paced manufacturing world, the role of the label machine is increasingly crucial. According to industry expert John Smith, “A label machine is not just a tool; it shapes the way products are perceived.” Label machines have evolved significantly, enhancing efficiency and accuracy in labeling processes. They help streamline operations.

Label machines improve product identification, compliance, and branding. They ensure that products are labeled accurately, reducing errors. However, not all manufacturers utilize these machines effectively. Some overlook the importance of choosing the right machine for their needs. This oversight can lead to delays and financial loss.

Additionally, the integration of technology in label machines invites both opportunity and complexity. Companies must balance innovation with practicality. Finding the right label machine remains a challenge for many. It requires careful consideration of factors like speed, cost, and scalability. The modern manufacturing landscape continues to demand more from these machines, pushing manufacturers to adapt.

The Importance of Label Machines in Modern Manufacturing Processes

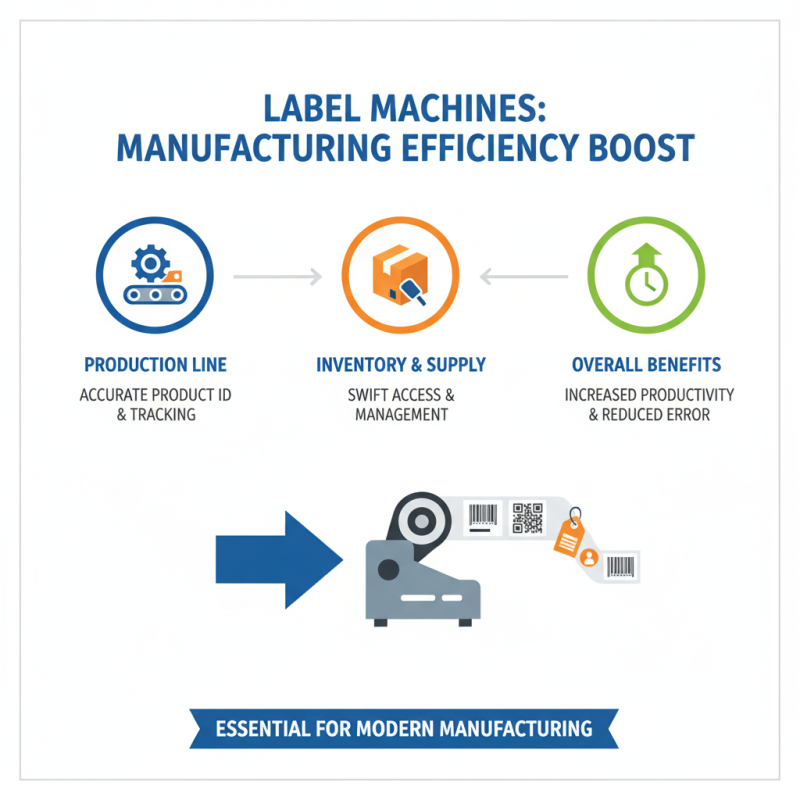

Label machines play a vital role in modern manufacturing processes. They enhance efficiency and ensure accurate product identification. In a fast-paced environment, labels are essential for tracking inventory and managing supplies. Whether on the production line or in storage, proper labeling aids in swift access. This organization ultimately boosts productivity.

However, the integration of label machines isn't always seamless. Some manufacturers face challenges in adapting to new technologies. Training staff can be time-consuming and costly. Additionally, machines may experience technical glitches. This can lead to delays and affect production schedules. Constant monitoring is required to minimize errors, impacting overall workflow.

Despite these hurdles, the benefits of label machines cannot be ignored. They promote consistency in branding and provide vital information to consumers. Accurate labels improve traceability of products in the supply chain. In conclusion, while challenges exist, the importance of label machines in manufacturing is undeniable.

Types of Label Machines Used in Various Industries

Label machines play a vital role in modern manufacturing. They ensure products are marked accurately and efficiently. Various industries utilize different types of label machines. Each serves unique purposes tailored to specific needs.

In food and beverage manufacturing, high-speed labelers apply labels swiftly to bottles and packages. This prevents bottlenecks during production. In pharmaceuticals, more precise labeling is crucial. Label machines here often include verification systems to ensure compliance. These machines can handle various materials, from films to paper.

Tips: Always consider the machine's compatibility with your product. Test labels for durability under various conditions. This avoids costly mistakes later.

For retail, label printers are prevalent. They allow businesses to create custom labels on demand. Such flexibility aids in marketing strategies. Yet, challenges arise. Some businesses may struggle with setup or maintenance. Regular training can help minimize errors.

Investing in the right type of label machine can streamline operations significantly. Evaluate the specific needs of your industry before choosing. The wrong option can lead to inefficiency and increased costs.

Tips: Schedule routine maintenance. It aids in preventing downtime. Research best practices for training staff to use machines effectively.

Key Features and Technologies in Label Machine Design

Label machines play a crucial role in modern manufacturing. These machines streamline production processes by ensuring that products are labeled accurately and efficiently. Recent industry reports indicate that the label machine market is expected to grow by 4.2% annually, driven by advancements in technology and rising demand for automation.

Key features of modern label machines include advanced printing technology and user-friendly interfaces. Many machines now incorporate digital printing, which allows for quicker label changes without downtime. Efficiency improves as companies adopt these machines. Studies show that businesses can increase output by up to 30% when using automated labeling solutions. However, not all manufacturers have made this transition, highlighting a gap that could hinder their competitiveness.

Another important aspect to consider is the integration of smart technologies. Some label machines now utilize IoT capabilities. This allows real-time monitoring of the labeling process and helps manage inventory effectively. Yet, many companies struggle with data integration into existing systems, leading to potential data silos. Addressing these challenges is essential for maximizing the efficiency benefits of labeling machines in manufacturing.

Impact of Labeling Efficiency on Production Line Performance

In modern manufacturing, labeling plays a crucial role in efficiency. The speed and accuracy of a labeling machine can significantly affect production line performance. When labels are applied quickly, products move faster through the assembly line. This speed reduces bottlenecks and keeps operations running smoothly. However, even a minor error during labeling can slow down the process.

Improperly applied labels can lead to confusion. Workers may need to stop the line to fix these mistakes. This downtime can accumulate, affecting overall productivity. Additionally, consumers may receive incorrectly labeled products, leading to dissatisfaction. In such cases, the consequences can extend beyond the production floor, impacting brand reputation.

To enhance efficiency, manufacturers must continually assess their labeling processes. Investing in advanced labeling technology may seem costly upfront, but the long-term benefits can be substantial. Regular training for staff on proper labeling techniques is also essential. Yet, it's easy to overlook these needs amidst daily pressures. A lasting commitment to refining labeling practices is vital for sustained performance in any production environment.

What is the Role of Label Machine in Modern Manufacturing? - Impact of Labeling Efficiency on Production Line Performance

| Metric | Before Labeling Efficiency Improvement | After Labeling Efficiency Improvement |

|---|---|---|

| Production Rate (units/hour) | 150 | 200 |

| Labeling Error Rate (%) | 5 | 1 |

| Downtime Due to Labeling Issues (hours/week) | 10 | 2 |

| Cost of Labeling Errors ($/week) | 500 | 100 |

| Customer Complaints Related to Labeling | 15 | 3 |

Future Trends in Label Machine Technology and Automation

Label machines are becoming crucial in modern manufacturing. Recent reports indicate that the market for label automation is expected to grow at a rate of 6.5% annually, reaching nearly $5 billion by 2027. This growth is driven by the increasing demand for efficient labeling solutions across various industries. Fast production cycles require quick and accurate labeling to meet supply chain needs.

One notable trend is the integration of smart technology in labeling machines. Many manufacturers are adopting IoT capabilities to optimize production. These machines can error-check in real-time, reducing waste. However, the push for automation also poses challenges. High initial costs may deter small businesses from investing in advanced labeling technology. Moreover, not all manufacturers can effectively adapt to these new systems, leading to potential bottlenecks in operations.

Sustainability plays a vital role in the future of labeling. Eco-friendly materials are gaining traction, with companies looking to reduce their carbon footprints. Still, this shift is not without its imperfections. The recycling of label materials remains problematic for many. Balancing innovation with environmental responsibility requires ongoing effort. Manufacturers must reflect on their practices and make informed choices for the future. The direction of label machine technology rests on these critical considerations.

The Role of Label Machines in Modern Manufacturing

This chart presents the performance metrics of label machines in modern manufacturing. It showcases their speed, accuracy, automation level, and cost, highlighting key areas of focus for future advancements in label machine technology.

Related Posts

-

Top 10 Label Printers for Small Businesses: Affordable and Efficient Options

-

How to Choose the Best Label Printer for Your Business Needs in 2023

-

How to Choose the Best Direct Thermal Labels for Your Business Needs

-

How to Choose the Best Label Maker for Your Home and Office Needs

-

Discover the Best Label Printer Machines of 2025: Top Picks & Reviews

-

Top Label Printers to Buy in 2025 Best Options for Every Need