How to Roll Labels Efficiently for Your Business?

In the fast-paced world of business, efficiency is crucial. When it comes to roll labels, proper handling can make a significant difference. Mark Johnson, a recognized expert in the roll labels industry, once stated, "Efficiency in labeling can elevate your brand." This insight highlights the importance of mastering the labeling process.

Many businesses struggle with label application. Misalignment or improper rolling can lead to wasted materials and time. It's essential to invest in the right tools and techniques. Understanding the nuances of roll labels is vital. Not every solution fits all situations, and trial and error can bring valuable lessons.

When considering roll labels, small details matter. Rewinding, speed, and adhesive quality can impact efficiency. Sometimes, techniques that appear straightforward may not yield the expected results. Reflecting on past mistakes can foster improvement. Embracing this learning journey is key for businesses aiming to streamline their labeling processes effectively.

Understanding the Importance of Efficient Label Rolling in Business

Efficient label rolling is crucial for any business that relies on product packaging. When labels are rolled poorly, it can cause delays and increase costs. Employees may spend extra time fixing tangled labels or dealing with misaligned rolls. This inefficiency can lead to frustration and affect overall productivity.

Understanding the different types of labels and their materials is essential. Some labels are thicker or might have a sticky residue that complicates rolling. Training staff on how to handle various labels can reduce these issues significantly. Regular practice can enhance their skills, but mistakes will still happen. A system to address these errors should be in place.

Incorporating tools, like label dispensers, can help streamline the rolling process. However, not all businesses can invest in high-end equipment. Many find themselves using manual methods, which can be time-consuming. Experimenting with different techniques may yield better results. Finding the right balance between speed and quality is vital. Each business must review its processes and make adjustments accordingly.

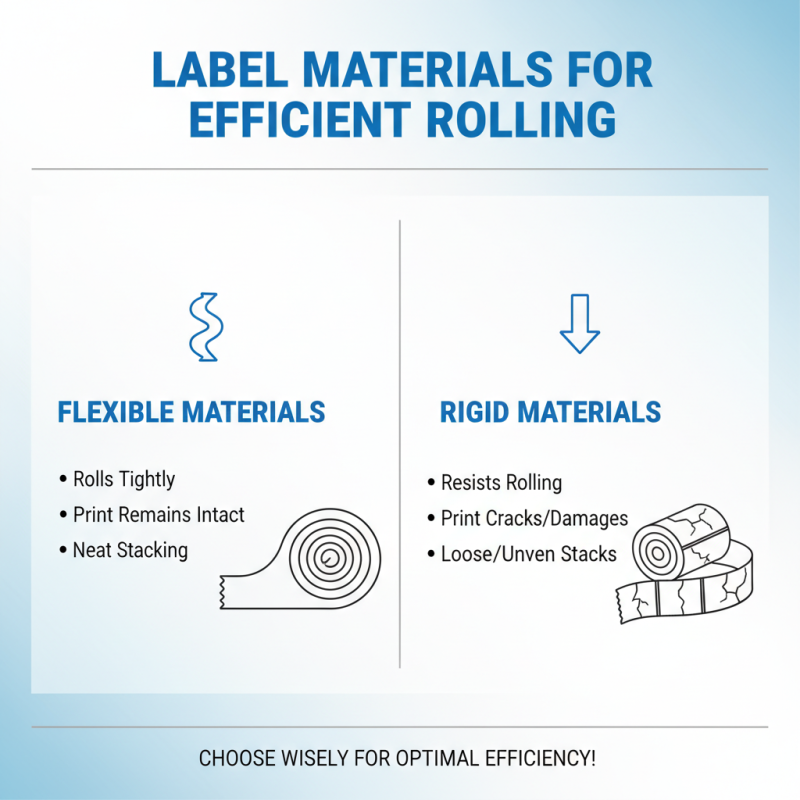

Choosing the Right Label Material for Optimal Rolling

Choosing the right label material is crucial for efficient rolling. Different materials have unique properties. Some are more flexible, while others are rigid. A flexible material can roll tightly without damaging the print. This is essential for labels that need to stack neatly.

Consider the adhesive type as well. A strong adhesive can prevent labels from peeling off, but it might also make rolling difficult. For instance, a label that sticks too well can tear during the rolling process. Experimentation can help you find the balance between adhesion and flexibility.

In addition, thickness matters. Thicker labels may add to the bulk, leading to issues during rolling. A common challenge is misalignment. Labels that are too thick can cause jams in the rolling machine. Always test different materials in small batches. Observe how they perform. Take notes on what works and what doesn’t. Adjust your choices based on this feedback.

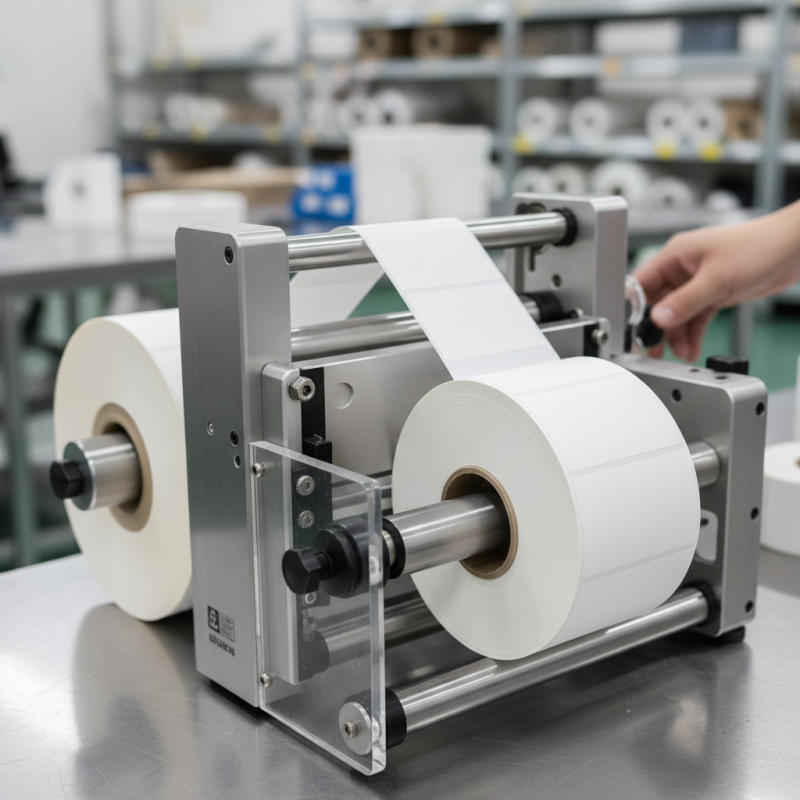

Essential Tools and Equipment for Rolling Labels Effectively

Rolling labels efficiently is crucial for many businesses. The right tools and equipment can drastically improve this process. Industry reports show that businesses can save up to 30% in labor costs by using automated labeling machines. These machines streamline the workflow and reduce manual errors.

Selecting the proper label applicator is vital. The applicator needs to match the label size and shape. Using a misaligned applicator can lead to waste and frustration. Some businesses report a loss of up to 5% of labels due to misapplication. Additionally, consider investing in quality label stock. Poor quality can lead to jams, which can slow down the labeling process significantly.

Lastly, having a well-organized workspace is essential for efficiency. Clutter can lead to confusion and delays. Keeping tools accessible can speed up the process. Regularly reassessing your setup can pinpoint areas for improvement. Making small changes can have a big impact on productivity. Don’t overlook the importance of ongoing training for employees. This keeps everyone on the same page and helps to avoid costly mistakes.

Step-by-Step Process for Rolling Labels Like a Pro

When rolling labels, the right approach makes a difference. Start by gathering all necessary tools. A label roll holder is essential. Ensure your workspace is clean and organized. This promotes efficiency.

Tips: Use a sharp blade to avoid tearing labels. A dull blade can create frustration. Keep a damp cloth nearby to catch any adhesive residue. This will help maintain a tidy work area.

Next, practice your rolling technique. Hold the roll firmly but not too tight. If the labels bunch up, you might need to adjust your technique. It’s okay to make mistakes and learn. This process can be tricky at first.

Tips: Align the labels straight to prevent misalignment. Misaligned labels can waste material and time. If the labels stick together, gently separate them without force. Patience is key here.

Common Challenges in Label Rolling and How to Overcome Them

Rolling labels efficiently can be a daunting task for many businesses. One common challenge is maintaining consistent tension on the label roll. If the tension is too loose, labels can unravel. If it's too tight, labels can become distorted. Monitor the tension closely during the rolling process. It may require adjustments throughout the day.

Another frequent issue is alignment. Misaligned labels create waste and frustration. They might stick together or misfeed in printing machines. Utilize guides and alignment tools to ensure proper positioning. Adjusting your setup periodically can save time and materials.

Finally, lack of proper training can lead to inefficiencies. Employees may not be familiar with the best practices for rolling labels. Offer regular training sessions to improve their skills. Sometimes, small changes in technique can lead to significant gains in efficiency. Encourage feedback from your team to identify areas for improvement.

Label Rolling Efficiency: Common Challenges and Solutions

This chart depicts common challenges faced in label rolling processes and their impact on overall efficiency. Understanding these challenges can help businesses improve their operations.

Related Posts

-

2025 Top 5 Roll Labels for Your Business Needs and Creative Projects

-

Top 10 Creative Bottle Labels Ideas to Elevate Your Product Presentation

-

How to Choose the Best Label Printer for Shipping to Boost Your Business Efficiency

-

Discover the Best Label Printer Machines of 2025: Top Picks & Reviews

-

How to Choose the Best Label Printer for Your Business Needs in 2023

-

How to Choose the Best Direct Thermal Labels for Your Business Needs